Overview

Warehouse floors are complex, dynamic systems where operational efficiency directly impacts profitability. In today's fast-paced logistics environment, queues form at docks, aisles get blocked by congestion, and picker paths expand silently—all leading to increased travel time, reduced throughput, and higher operational costs. Traditional Business Intelligence (BI) systems provide historical data that shows you what happened yesterday, but by then, the damage is already done. Warehouse managers need actionable insights in real-time to make immediate decisions that prevent bottlenecks from cascading into larger operational failures.

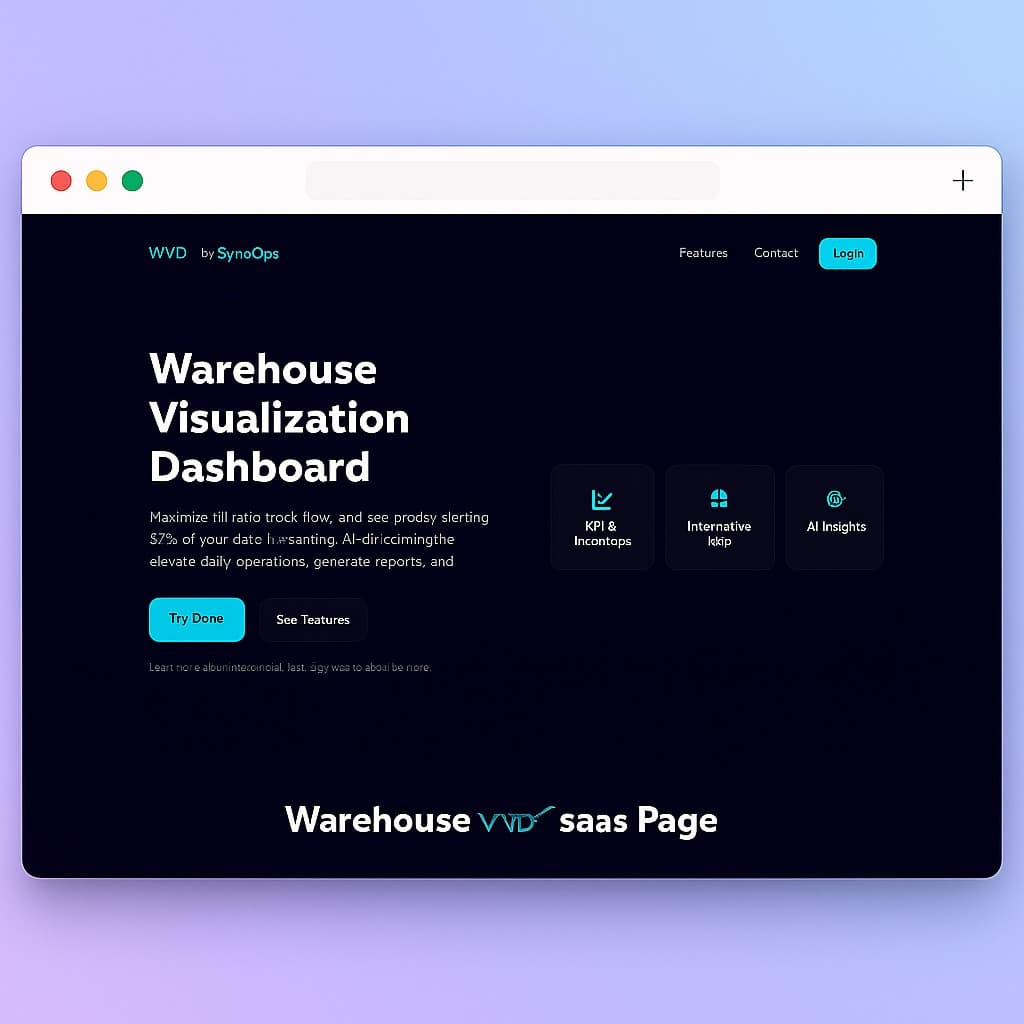

WVD (Warehouse Visualization Dashboard) revolutionizes warehouse operations by transforming WMS and IoT signals into live, actionable heatmaps that update within seconds. Unlike traditional dashboards that refresh every hour or day, WVD provides a real-time view of the last 60 seconds of activity across your entire warehouse floor. This enables floor leads and managers to see congestion patterns as they develop, identify hot zones before they become critical bottlenecks, and make data-driven decisions to redirect labor, re-slot fast-moving items, or open alternate routes—all in real-time.

The system transforms raw operational data into intuitive visual representations that highlight activity intensity, stock flow patterns, and congestion areas. By applying intelligent decay functions and spatial grid analysis, WVD ensures that the visual representation stays fresh and responsive to current conditions. When thresholds are breached—such as excessive dwell time in a particular zone or unusual activity spikes—the system overlays recommended actions directly on the heatmap, guiding managers toward optimal interventions.

This real-time visibility cuts the feedback loop from hours to minutes, enabling proactive management instead of reactive firefighting. Teams can shorten pick paths, reduce backtracking, stabilize zone flow, and improve overall warehouse throughput—all while reducing labor costs and improving worker satisfaction through more efficient routing.

How it works

- Ingests WMS events (picks, putaways, staging) and RTLS/IoT beacons

- Builds a spatial grid for each zone and updates activity intensity per cell

- Applies decay functions to keep the view fresh and responsive

- Overlays recommended actions when thresholds are breached

Live views cut the feedback loop from hours to minutes. Leads can redirect labor, re-slot fast movers, or open alternate aisles before backlogs compound.

Benefits

- Lower Travel Time — Shorter pick routes with fewer detours

- Higher Throughput — Smoother zone flow and fewer choke points

- Better Labor Use — Leads focus where the floor actually needs help

Implementation/Checklist

- Define site map and zones

- Connect WMS streams and optional RTLS/IoT

- Calibrate heat thresholds with historical data

- Pilot in one zone, then expand weekly

FAQ

Will it work without RTLS?

Yes. WMS events alone produce highly actionable heatmaps; RTLS adds precision.

How real-time is "real-time"?

The visual refreshes within seconds; aggregation windows are configurable.